Refining the Technique of Mounting Front Easily Accessible Light-Emitting Diode Modules for Peak Operation and Durability

Installing forward accessible LED panels is an essential job that necessitates detailed planning and implementation to ensure best performance and lifespan. LED screens are commonly used in various applications, including business spaces, events, and media rooms due to their high-quality displays and energy efficiency. forward serviceable displays offer the convenience of maintenance and exchange without needing entry to the behind of the screen. This feature makes them especially useful in confined installations where behind access is not possible. To master the setup procedure, comprehending the elements, tools, and techniques involved is critical.

The initial step in setting up face accessible digital panels is to collect all necessary materials and tools. This involves the digital panels themselves, a sturdy mounting bracket, wiring components, and safety gear such as safety gloves and eye protection. It is also vital to have a power source immediately on hand. Knowledge with the screen requirements is critical, as each model may have specific setup criteria. Additionally, reviewing the supplier’s guidelines will offer direction into the best approaches for setting up and wiring the screens successfully.

When all supplies are at hand, the next phase entails setting up the setup site. This includes measuring the area to ensure that the LED screens will align properly within the specified framework. Proper dimensions assist eliminate later issues related to size or positioning. Cleaning the space before mounting is also necessary to ensure that dirt or residue does not affect the mounting glue or support hardware. It is recommended to have at least two technicians involved in this task, as lifting oversized panels can be challenging and requires careful handling.

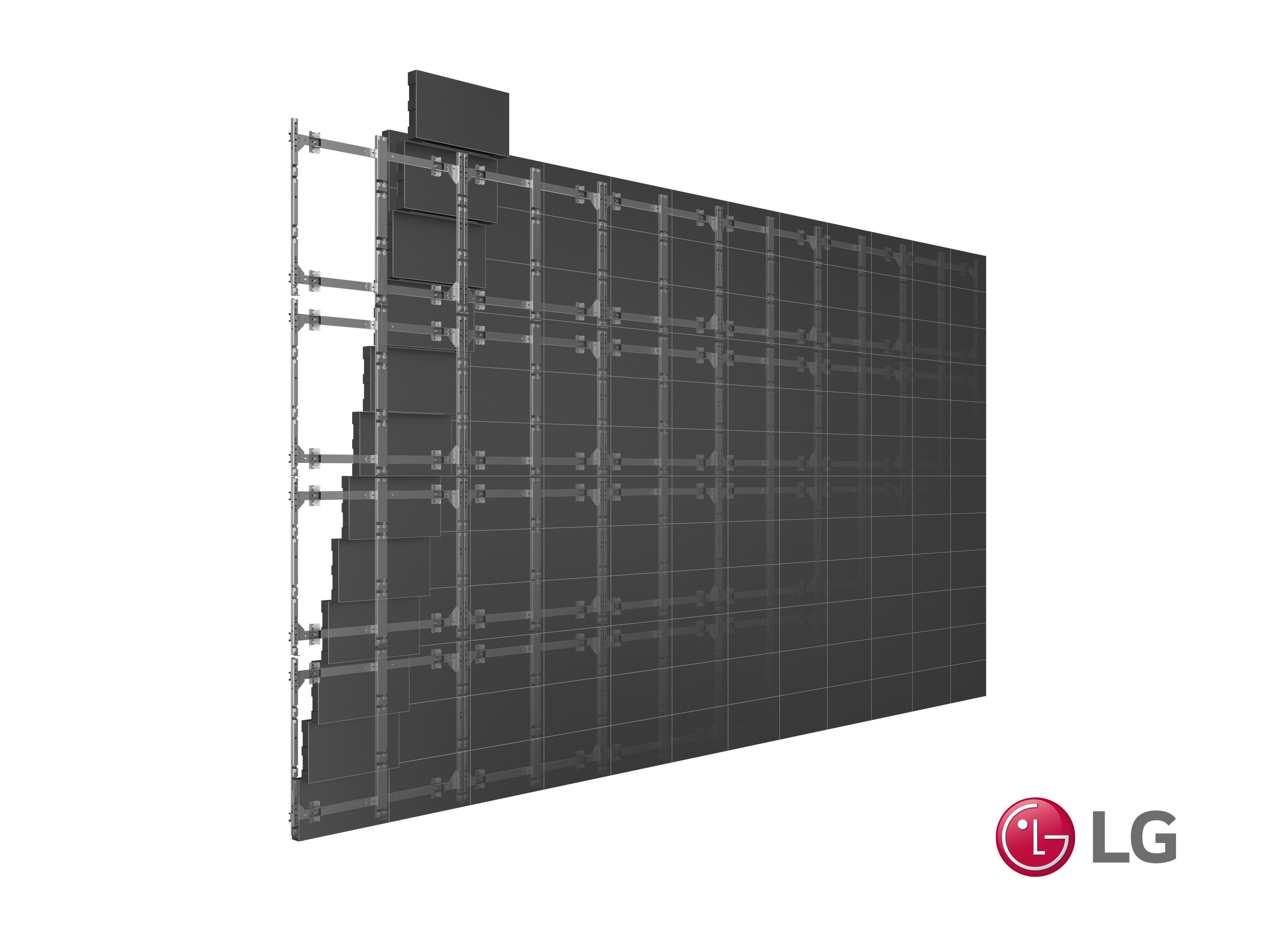

The actual mounting of front serviceable LED panels commences with fastening the installation bracket to a stable foundation. The structure should be balanced and adjusted accurately since any misplacement can impact the total screen clarity. After stabilizing the bracket, it is time to connect the cables. This procedure requires connecting each screen to a supply while verifying that connections are properly managed to reduce snagging or damage over time. Once everything is wired correctly, the panels can be carefully attached to the mounting frame according to the manufacturer’s manual.

Following mounting the face maintainable light-emitting diode panels, verifying their functionality is vital for securing best results. This requires examining for true color, next page brightness levels, and any potential dead pixels. Consistent maintenance inspections should be planned to increase the longevity of the light-emitting diodes and ensure they remain operating at their peak. By adhering to these steps for installation and maintenance, technicians can experience high-quality visuals while maximizing their investment in light-emitting diode systems for years to look at this website come.